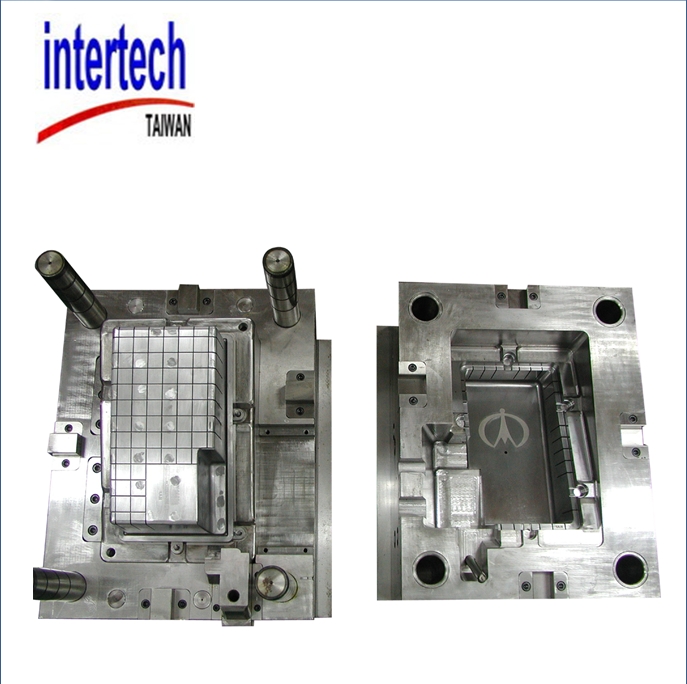

Plastic Injection Molding Tools / Tooling for Custom Service - Intertech

Plastic Injection Molding Tools Profile Introduction

Intertech is based 100% in Taiwan with more than 30 years experience. We help customer to make customized plastic injection molds, particularly in the material of high quality steel purely imports from German and Japan. We commonly use mold steel such as P20 (1.2311), H13 (1.2344) and Starvax 420 (stainless steel), and with simple maintenance, all these tools can run min. 200000 ~ 1000000 shots under ideal operational condition.

Plastic Injection Molding Tools Profile Introduction

Intertech is based 100% in Taiwan with more than 30 years experience. We help customer to make customized plastic injection molds, particularly in the material of high quality steel purely imports from German and Japan. We commonly use mold steel such as P20 (1.2311), H13 (1.2344) and Starvax 420 (stainless steel), and with simple maintenance, all these tools can run min. 200000 ~ 1000000 shots under ideal operational condition.

Customized Plastic Injection Molding Tools support

Intertech is based 100% in Taiwan with more than 30 years experience. We help customer to make customized plastic injection molds, particularly in the material of high quality steel purely imports from German and Japan. We commonly use mold steel such as P20 (1.2311), H13 (1.2344) and Starvax 420 (stainless steel), and with simple maintenance, all these tools can run min. 200000 ~ 1000000 shots under ideal operational condition.

Taiwan Mold and Molding Factory

l Over 30 years experience, Intertech offers customers with intelligent and cost saving mold and molding solutions to their production need in Taiwan.

l We can make the quality molds for your most complex parts and projects, including mold manufacturing, assembly, testing, and packaging.

l With 30 years experience, we manage very well in contract manufacturing, including the material selection, customer design checking, engineering discussion, tooling, pilot run, mass production, post operations, quality control and supply chain management.

l We have excellent mold making lead time, some molds 40 days, some molds even 35 days, up to your parts design.

Tools starts with 30-50% down payment, with the rest paid only after you are satisfied with the testing sample.

We build customized molding tools for small businesses or large manufacturers.

We can make the mold and molding product project for the plastics, silicone, liquid Silicone rubber and metal materials. We offer the best service with the best price.

Price varies up to the type of molding tools. Typically a small molding tool costs from $1000 - $5000, and larger ones from $3000 to $30000. Please contact us for details.

For Mold Inquiry, Customer Must prepare:

1. Product drawing with 2D(.dwg)and 3D (.igs, .stp…etc)?

2. Advise product material (ex. Plastic ,rubber, silicone rubber or metal…etc )?

3. Molding machine tonnage size and platen size?

4. The cavity number of the mold that you want us to quote?

5. Mold steel grade that you want us to quote?

6. Hot runner or cold runner mold required?

7. Mold gating inlet preferred?

8. Mold ejection way preferred?

9. Other related information required …(ex. Polishing , texture, engraving …etc)

For Molding Products Inquiry , customer must prepare:

1. Products material required? (ex. Plastics, rubber , silicone , metal…etc)

2. Products quality required in total?

3. Delivery time required?

4. Post machining or not information? (ex. Chromed plate.., painting …etc)

5. Assembly or not information?

6. Packing or not information?

Quick service: 100% in Taiwan

l Mold making

l Injection molding

l Tool and die making

l Tool and die production

l DFM

l Mold flow

l Conform your Industrial engineering to tooling engineering

project management by experienced engineers

l Engineering discussion is available

Messenger

Messenger