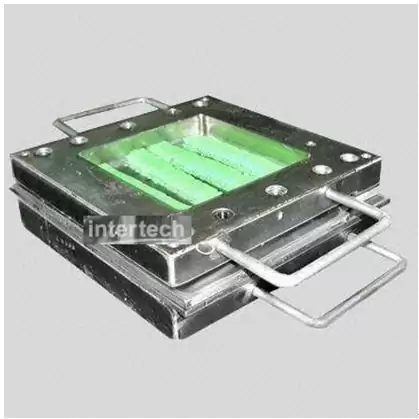

Rubber compression mold

Intertech is a professional compression mold, rubber mold, precision compression mold,compression moulding services Supplier. Find more compression mold, rubber mold, compression moulding services information here or contact us for full service.

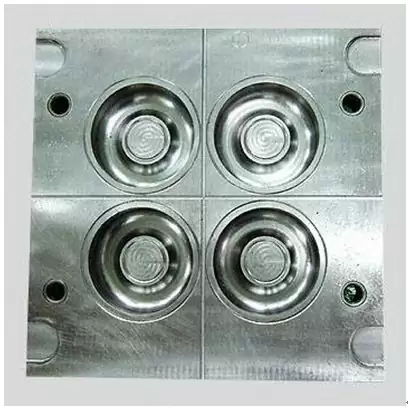

*4 cavity rubber hot compression mold

* with S50C mold steel, multi-layer mold plates.

* cheap in mold cost, but cycle time could be very long, up to your product design and weight.

* please send your project with detailed 2D, 3D, photos, samples, we will send our evaluation report.

Intertech is a professional compression mold, rubber mold, precision compression mold,compression moulding services Supplier. Find more compression mold, rubber mold, compression moulding services information here or contact us for full service.

*4 cavity rubber hot compression mold

* with S50C mold steel, multi-layer mold plates.

* cheap in mold cost, but cycle time could be very long, up to your product design and weight.

* please send your project with detailed 2D, 3D, photos, samples, we will send our evaluation report.

The Highlight Point of Rubber Mold

Rubber molding are used in industries that span automotive, defense, sporting goods, medical devices and consumer products. Liquid silicone rubber is usually made from low-viscosity, two-component materials.

-Capable to making silicone rubber molds in hot compression way or injection way.

-Mold cavity and mold size can be discussed upon your own requirements.

-Produced from SGS, FDA approved silicone rubber and LSR materials.

- We usually use silicone rubber in the 40 to 70 shore A depending on customized requirements.

-Supply with minimized flash free & mark free molded silicone products.

- Available in dealing with OEM manufacturing, ODM manufacturing, customized production, contract manufacturing for silicone rubber mold & molding projects in Taiwan.

Silicone parts mold and molding application examples : Our mold development for silicone has a wide range of product application lines as such : ear plug, label, pad, gasket, protective frame, mobile phone protective cover, keypad, silicone rubber cord, check valve …etc.

More Applications:

-in Aerospace (silicone molded seals…)

-in Medical and health care (silicone molded membranes, seals…)

-in Electronic (connection insulators…)

-in Cooking / Baking (silicone molded spatulas…)

-in Agricultural (seals…)

Liquid Silicone Rubber (LSR) parts mold and molding application examples :

Available to produce extensive coloring or high transparency option in the finished molded LSR products. Capable in managing medical grade, food grade, normal grade liquid . Silicone molded products projects.

Our mold development for liquid silicone has a wide range of product application lines as such : baby nipple, pacifiers, seals, membrances, smooth surface LSR parts, respirator, medical mask, check valve, mouth guard, tension ring, diving masks…etc.

For mold design , ..

- The software we use includes Pro-Engineer, I-Deas, Cimetron, Auto-Cad & Solidworks.

- Cutomer can send 2D, 3D, by .igs .stp, formats to us.

- We can provide mold flow analysis service.

- Mold design (with the best optimized mold water channel arrangement design and the best cycle time performance consideration design)

In addition, CNC milled prototype, 3D printing prototype, prototype mold making service, fixture / jig making or welding horn design and making are available in Intertech with good experience !

We need 2D, 3D parts design to start our job, we can sign NDA (if needed)

For mold making :

When making mold project, per customer’s requirement for mold steel material, we choose the suitable mold steel grade for our customers. We have high quality German and Japan imports mold steel material to proceed our mold project making. Then, the gating way will be discussed, the mold surface will be discussed, the mold cooling channel design will be checked, the operation style will be discussed, the molding machine size will be determined and the mold mechanism in actual production movement will all be checked as well. Only after our mold engineers discussing with our customers for the mold engineering in detail, we will proceed with our mold making job.Mold Order Process

Mold Shipping Process

For Mold Inquiry , customer must prepare:

- Product drawing with 2D(.dwg)and 3D (.igs, .stp…etc)?

- Advise product material (ex. Plastic ,rubber, silicone rubber or metal…etc )?

- Molding machine tonnage size and platen size?

- The cavity number of the mold that you want us to quote?

- Mold steel grade that you want us to quote?

- Hot runner or cold runner mold required?

- Mold gating inlet preferred?

- Mold ejection way preferred?

- Other related information required …(ex. Polishing , texture, engraving …etc)

For Molding Products Inquiry , Customer must prepare:

- Products material required? (ex. Plastics, rubber , silicone , metal…etc)

- Products quality required in total?

- Delivery time required?

- Post machining or not information? (ex. Chromed plate.., painting …etc)

- Assembly or not information?

- Packing or not information?

Quick service: 100% in Taiwan

l Mold making

l Injection molding

l Tool and die making

l Tool and die production

l DFM

l Mold flow

l Conform your Industrial engineering to tooling engineering

project management by experienced engineers

l Engineering discussion is available

Taiwan Mold and Molding Factory:

l Over 30 years experience, Intertech offers customers with intelligent and cost saving mold and molding solutions to their production need in Taiwan.

l We can make the quality molds for your most complex parts and projects, including mold manufacturing, assembly, testing, and packaging.

l With 30 years experience, we manage very well in contract manufacturing, including the material selection, customer design checking, engineering discussion, tooling, pilot run, mass production, post operations, quality control and supply chain management.

l We have excellent mold making lead time, some molds 40 days, some molds even 35 days, up to your parts design.

Intertech - Quick Look :

l If you want to have your product to reverse manufacture, we can help you with our rich manufacturing experience.

l If your current supplier is becoming cost prohibitive, we can help you to find a cost effective solution.

l You can send samples, and we can design, manufacturer and ship a finished product to USA or wherever the place you want us to export.

l We can work out total cost of the project and the cost per piece.

l If you are saling some products now, we can help you to develop better products idea and manufacturing it with the best possible solution supply chain in Taiwan, including product packing and printing supply.

Messenger

Messenger