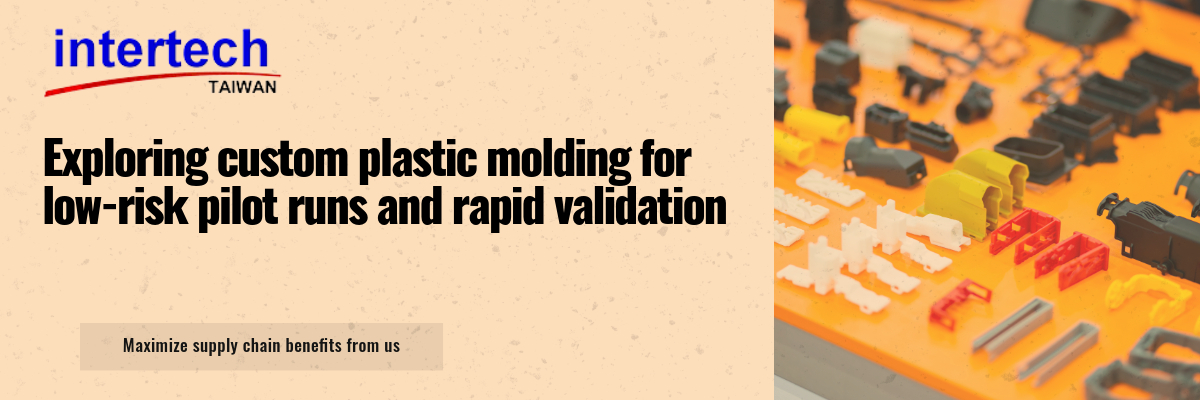

Exploring Custom Plastic Molding for Low-Risk Pilot Runs and Rapid Validation

Exploring Custom Plastic Molding for Low-Risk Pilot Runs and Rapid Validation

Custom plastic molding is an invaluable process for businesses looking to mitigate risks and accelerate product validation before committing to full-scale production. Low-risk pilot runs provide essential insights into product feasibility, performance, and market acceptance, enabling rapid adjustments and refinements. This article highlights the benefits and strategies of employing custom plastic molding for effective pilot production and validation.

The Importance of Low-Risk Pilot Runs

Pilot runs are small-scale production tests conducted to:

-

Validate product design and functionality.

-

Identify and resolve production challenges early.

-

Evaluate consumer response and market potential.

-

Minimize financial risks associated with full-scale production.

Leveraging custom plastic molding during this critical phase allows companies to quickly identify potential issues, refine designs, and streamline subsequent manufacturing processes.

Advantages of Custom Plastic Molding for Pilot Runs

1. Cost Efficiency

Custom molding minimizes upfront investment by allowing the production of smaller quantities without the financial burden of high-volume tooling and manufacturing costs.

2. Flexibility and Rapid Iteration

The adaptability of custom plastic molds means designs can be rapidly modified based on pilot run feedback, reducing time to market and improving overall product quality.

3. Accurate Market Testing

Producing a precise representation of the final product enables realistic market testing, gathering genuine consumer insights before full-scale rollout.

4. Reduced Time to Market

Quick turnaround times in custom molding help expedite the validation process, allowing businesses to swiftly transition from concept to commercialization.

Key Considerations for Effective Custom Plastic Molding

Material Selection

Selecting the appropriate plastic material is crucial, balancing performance characteristics such as strength, durability, flexibility, and cost-effectiveness.

Mold Design

Optimized mold designs tailored for low-volume production facilitate quick adjustments, minimize costs, and ensure high-quality, precise components.

Prototype Quality and Accuracy

Ensuring prototypes closely replicate intended final products is vital for reliable testing outcomes and accurate market feedback.

Scalability

Consider the potential for scaling production easily from pilot runs to larger batches without significant redesign or additional costs.

Choosing the Right Partner for Custom Plastic Molding

When selecting a molding partner, prioritize:

-

Proven expertise in custom and prototype molding.

-

Strong track record of rapid prototyping and responsive iteration.

-

Comprehensive quality control processes.

-

Capabilities in flexible, scalable manufacturing.

Why INTERTECH is Your Ideal Partner for Low-Risk Pilot Runs

INTERTECH (https://www.taiwanmoldmaker.com/) specializes in custom plastic molding solutions ideal for pilot runs and rapid validation:

-

Rapid Prototyping Capabilities: Swift development of high-quality, precise prototypes.

-

Experienced Engineering Team: Expert support in mold design optimization and material selection.

-

Flexible Manufacturing Solutions: Adaptability to efficiently manage small pilot runs and larger production scales.

-

Advanced Technologies: State-of-the-art injection molding equipment and comprehensive quality assurance systems.

Conclusion

Custom plastic molding for low-risk pilot runs offers a strategic advantage in product development, enabling businesses to validate designs effectively, minimize risks, and optimize production processes before scaling. Partnering with a specialized provider like INTERTECH ensures seamless transitions from prototyping to full production, positioning your business for successful market entry and sustained growth.

Ready to discuss your pilot run and rapid validation needs? Contact INTERTECH today: https://www.taiwanmoldmaker.com/contact.