Compression molding

Intertech is a leading supplier for Compression molding, making all kinds of compression moulding and compression moulding process and silicone rubber molding ,rubber compression molding process,silicone compression molding,Rubber compression molding,rubber liquid silicone silicon molded custom in Taiwan. Intertech's services include prototyping, tooling, lab testing, production and assembly.

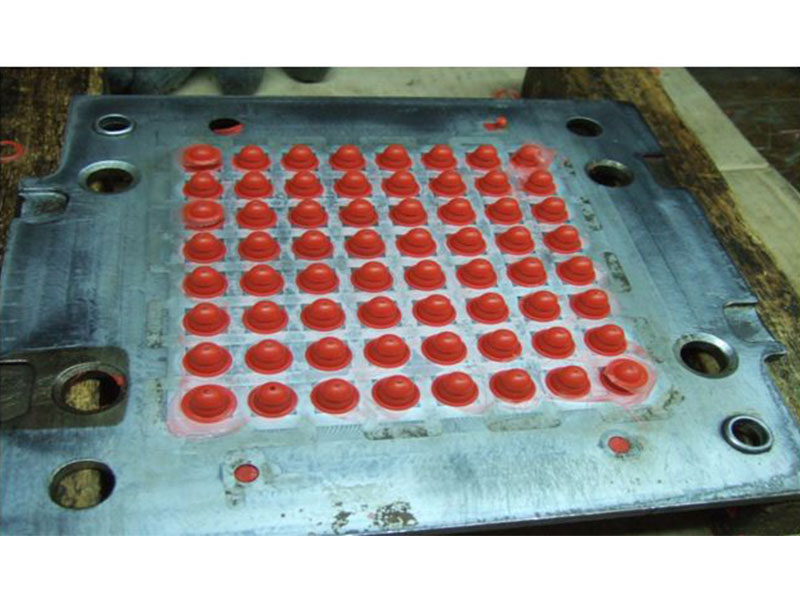

The Compression Molding Project Example We Manage :

- Except our silicone mold experiences, we also manufacture silicone molding with great silicone molding stability which enables such silicone parts to resist extreme temperatures of heat and cold.

- We have rich experience in making silicone molding for producing FDA approval food grade silicon products, medical grade silicone products, general grade silicon products and industrial grade silicone products, rubber liquid silicone silicon molded custom.

- Hardness of our silicone molding material usually are 40~50 shore A. This can be discussed case by case.

- We work closely with our customers to provide well designed silicone mold and molding service, and cost-effective silicone molding products service.

- We specialized in high volume silicone olding , over-molding silicone onto plastics & metal parts.

-mold cavity no. & mold size: per customer’s drawing and customer’s requirement.

We provide handle mould of good quality and competitive price.

Intertech is a leading supplier for Compression molding, making all kinds of compression moulding and compression moulding process and silicone rubber molding ,rubber compression molding process,silicone compression molding,Rubber compression molding,rubber liquid silicone silicon molded custom in Taiwan. Intertech's services include prototyping, tooling, lab testing, production and assembly.

The Compression Molding Project Example We Manage :

- Except our silicone mold experiences, we also manufacture silicone molding with great silicone molding stability which enables such silicone parts to resist extreme temperatures of heat and cold.

- We have rich experience in making silicone molding for producing FDA approval food grade silicon products, medical grade silicone products, general grade silicon products and industrial grade silicone products, rubber liquid silicone silicon molded custom.

- Hardness of our silicone molding material usually are 40~50 shore A. This can be discussed case by case.

- We work closely with our customers to provide well designed silicone mold and molding service, and cost-effective silicone molding products service.

- We specialized in high volume silicone olding , over-molding silicone onto plastics & metal parts.

-mold cavity no. & mold size: per customer’s drawing and customer’s requirement.

We provide handle mould of good quality and competitive price.

Compression molding

We supply two types of silicone molding services:

- injection silicone molding:

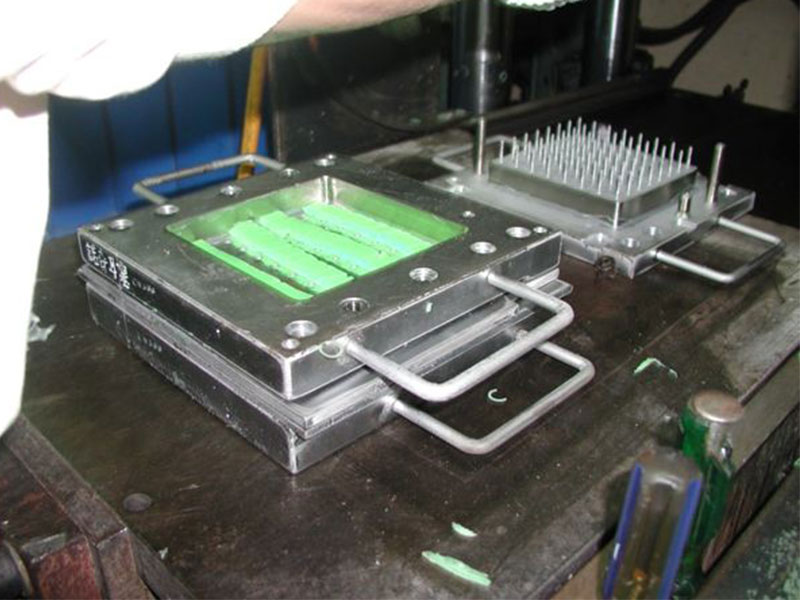

-We provide both cold runner silicone injection molds (molding) and hot runner silicone injection molds (molding). - hot compression silicone molding:

-we use this method to develop & produce silicone molded parts especially with metal reinforcement.

Assembly and automation

- Automated assembly

- Semi-automated assembly

- Manual assembly

- Printing and packaging

Silicone molding

-Capable to making silicone rubber molds in hot compression way or injection way.

-Mold cavity and mold size can be discussed upon your own requirements.

-Produced from SGS, FDA approved silicone rubber and LSR materials.

- We usually use silicone rubber in the 40 to 70 shore A depending on customized requirements.

-Capable to manufacture tiny/small/little silicone molded parts for our customers.

-Supply with minimized flash free & mark free molded silicone products.

- Available in dealing with OEM manufacturing, ODM manufacturing, customized production, contract manufacturing for silicone rubber mold & molding projects in Taiwan.

Silicone parts mold and molding application examples : Our mold development for silicone has a wide range of product application lines as such : ear plug, label, pad, gasket, protective frame, mobile phone protective cover, keypad, silicone rubber cord, check valve …etc.

More Applications:

-in Aerospace (silicone molded seals…)

-in Medical and health care (silicone molded membranes, seals…)

-in Electronic (connection insulators…)

-in Cooking / Baking (silicone molded spatulas…)

-in Agricultural (seals…)

Liquid Silicone Rubber (LSR) parts mold and molding application examples : Available to produce extensive coloring or high transparency option in the finished molded LSR products.

Capable in managing medical grade, food grade, normal grade liquid . Silicone molded products projects.

Our mold development for liquid silicone has a wide range of product application lines as such : baby nipple, pacifiers, seals, membrances, smooth surface LSR parts, respirator, medical mask, check valve, mouth guard, tension ring, diving masks…etc.

Intertech is one of the leading company in silicone compression molding industry with its high quality and competitive price.

We provide silicone compression molding.

Our goal is to provide customers products of high quality, competitive price, and superior services.

For mold design, …

- The software we use includes Pro-Engineer, I-Deas, Cimetron, Auto-Cad & Solidworks.

- Cutomer can send 2D, 3D, by .igs .stp, formats to us.

- We can provide mold flow analysis service.

- Mold design (with the best optimized mold water channel arrangement design and the best cycle time performance consideration design)

In addition, CNC milled prototype, 3D printing prototype, prototype mold making service, fixture / jig making or welding horn design and making are available in Intertech with good experience !

We need 2D, 3D parts design to start our job, we can sign NDA (if needed)

For mold making:

When making mold project, per customer’s requirement for mold steel material, we choose the suitable mold steel grade for our customers. We have high quality German and Japan imports mold steel material to proceed our mold project making. Then, the gating way will be discussed, the mold surface will be discussed, the mold cooling channel design will be checked, the operation style will be discussed, the molding machine size will be determined and the mold mechanism in actual production movement will all be checked as well. Only after our mold engineers discussing with our customers for the mold engineering in detail, we will proceed with our mold making job.

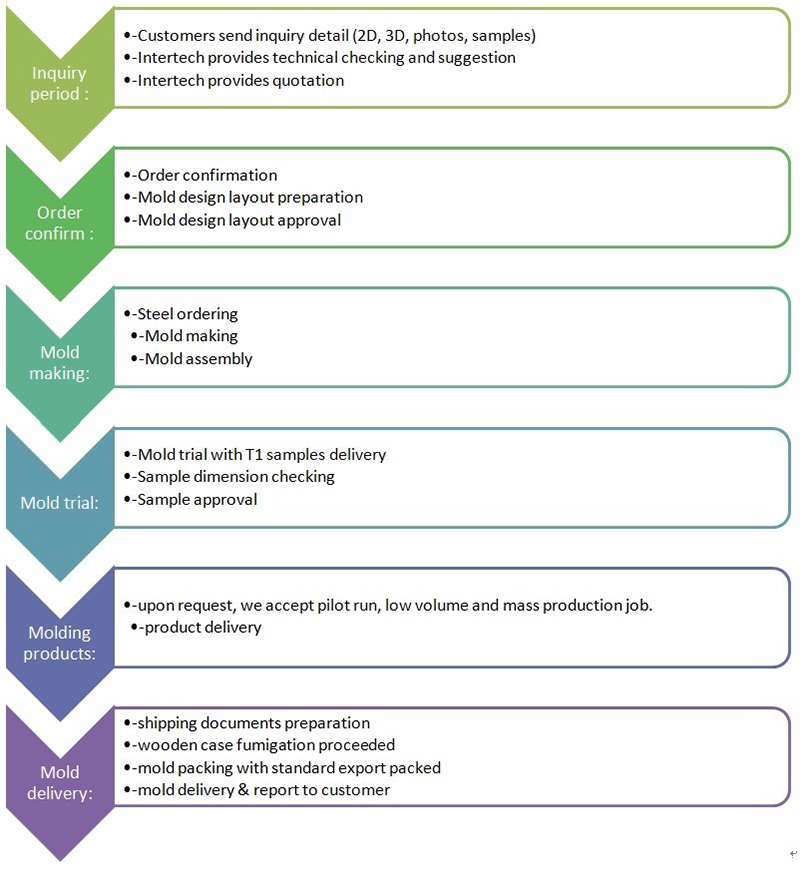

Mold Order Process

Mold Shipping Process

Intertech is professional injection mold and molding manufacture.

We have more than 25 years of history working in injection mold and molding. Our injection mold has good reputation in countries like Germany , Denmark , Sweden , and USA market. If you have any mold and molding for injection , compression silicone rubber , punch die develop inquiry , please send us your inquiry with 2D and 3D drawing.

one-stop-shop” for all your mold & molding needs

Are you a crowd funding project leader or a great ideal inventor or an industrial product designer or a production factory manager or a project manager or a new parts business investor? , Intertech will be your good working partner in Taiwan who makes your dreams come true.

Intertech – Expert of Plastic Injection Industry (mold development & injection molding service)

<> Normally, a general mold making factory focus only on plastic injection mold, but Intertech also gets deeply involved in the silicone compression mold and metal punch die. Therefore, no matter you have plastic parts, silicone rubber parts or metal parts project, we can all manage for its tooling and production job for you here in Taiwan our factory.

For Parts: bulk or individual pack, upon customer's demands with exported carton box.

For Mold: Standard exported wooden box packed, fumigation process (upon required).

Intertech is professional injection mold and molding manufacture. We have more than 25 years of history working in injection mold and molding. Our injection mold has good reputation in countries like Germany , Denmark , Sweden , and USA market. If you have any mold and molding for injection , compression silicone rubber , punch die develop inquiry , please send us your inquiry with 2D and 3D drawing.

For Mold Inquiry, Customer Must prepare:

- Product drawing with 2D(.dwg)and 3D (.igs, .stp…etc)?

- Advise product material (ex. Plastic ,rubber, silicone rubber or metal…etc )?

- Molding machine tonnage size and platen size?

- The cavity number of the mold that you want us to quote?

- Mold steel grade that you want us to quote?

- Hot runner or cold runner mold required?

- Mold gating inlet preferred?

- Mold ejection way preferred?

- Other related information required …(ex. Polishing , texture, engraving …etc)

For Molding Products Inquiry , customer must prepare:

- Products material required? (ex. Plastics, rubber , silicone , metal…etc)

- Products quality required in total?

- Delivery time required?

- Post machining or not information? (ex. Chromed plate.., painting …etc)

- Assembly or not information?

- Packing or not information?

Messenger

Messenger