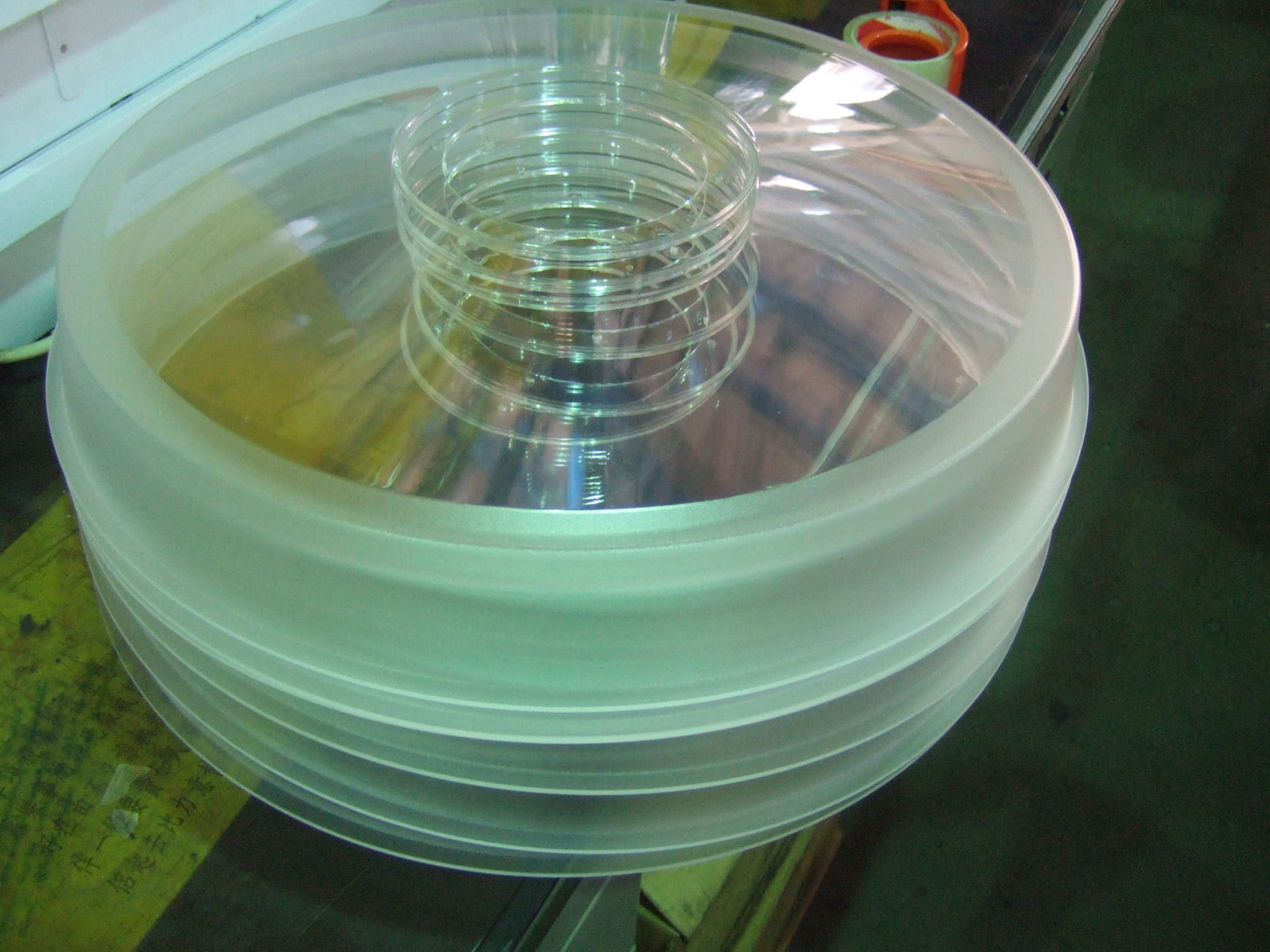

Beacon light mold

Beacon lights flashing mold introduce

Intertech has good experience in making beacon light mold and job for many famous brands, such as Philips, Thorn, Industial…etc.

Beacon lights flashing mold introduce

Intertech has good experience in making beacon light mold and job for many famous brands, such as Philips, Thorn, Industial…etc.

Beacon light mold

Intertech has good experience in making beacon light mold and job for many famous brands, such as Philips, Thorn, Industial…etc.

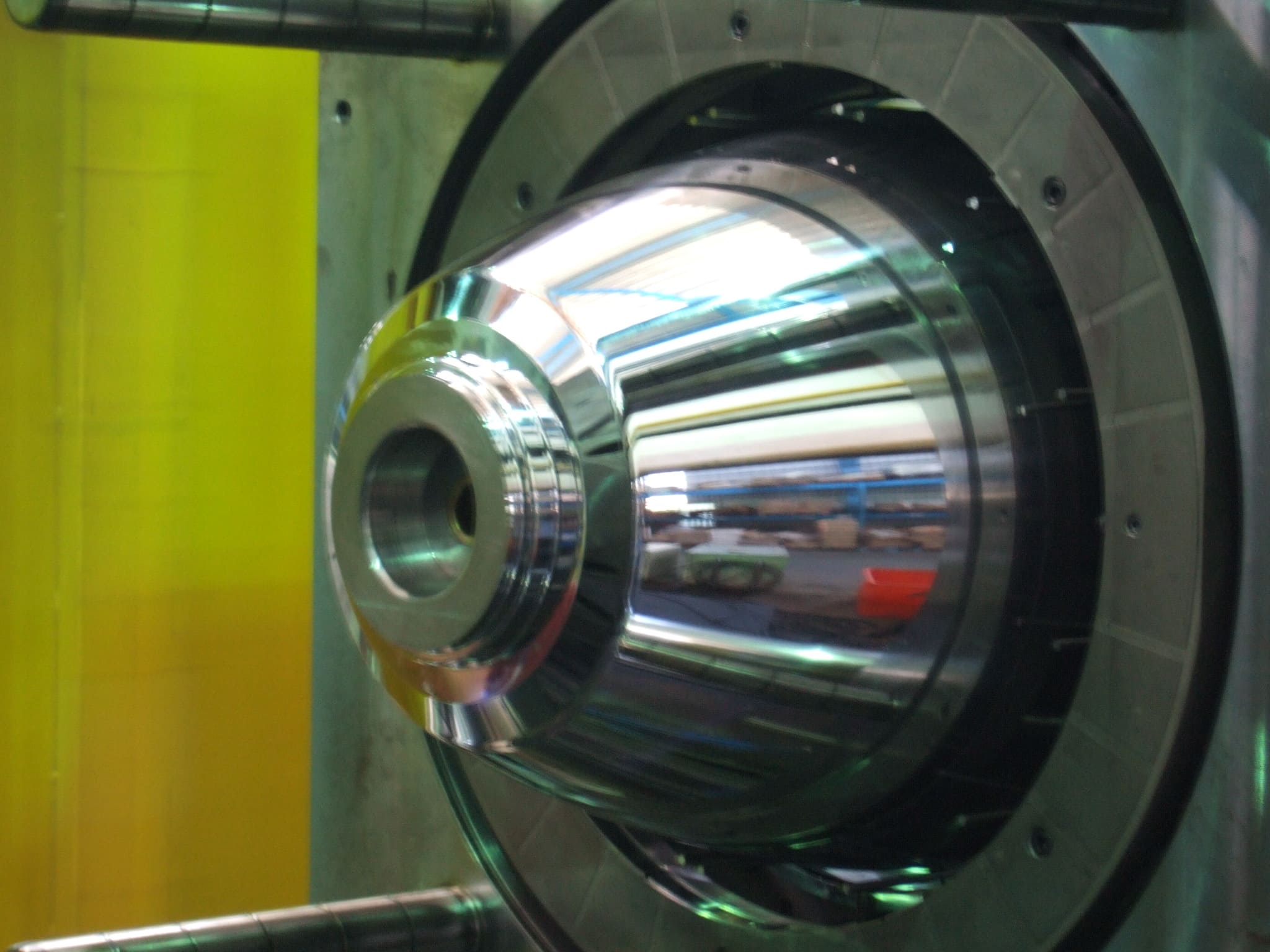

For making such project,the beacon light mold design is quite important…optimized mould tooling cooling, ideal beacon light mold injection, perfect polishing, good cycle time..etc.

Intertech has really good mold making experience and molding experience for such beacon light mold project, including round shape, square shape, rectangular shape light fixture parts project…etc.

Welcome to send us similar project to get our good experience and service for this beacon light mold making and molding fabrication.

The Highlight Point of beacon light mold

The Information of beacon light mold

|

Product Name |

mold |

|

Plastic Material |

PP , PE , ABS , POM , PET, PBT, Nylon + GF…..etc. |

|

Steel of Cavity & Core |

Up to customer’s budget and productivity required, |

|

Steel of Mold Base |

Up to customer’s budget and requirement , we suggest different mold base steel to clients. Normal used material S50C, or P20 |

|

No. of Cavity |

Customized |

|

Hardness of Cavity & Core |

Pre-Hardenss Steel : HRC 30~32+-1* |

|

Core pulling or Ejection system |

Depends on the Products. |

|

Mould Accessories |

Compatible to DME/ HASCO Standard. |

|

Cooling System |

In Core : Baffle or By pass cooling |

|

Surface Finish |

Up to the prodct’s requirement, Normal used : Texture, EDM maching , Polishing |

|

Mold Life |

Up to mold steel grade, under ideal operation condition, |

|

Runner |

1. Cold runner |

|

Delivery time |

40~50 days , presenting T1 samples |

|

Packing |

Standard Wooden Case |

|

Production |

We can also provide Pilot Run production and molding production |

For plastic mold design, …

1. The software we use includes Pro-Engineer, I-Deas, Cimetron, Auto-Cad & Solidworks.

2. Cutomer can send 2D, 3D, by .igs .stp, formats to us.

3. We can provide mold flow analysis service.

4. Mold design (with the best optimized mold water channel arrangement design and

the best cycle time performance consideration design)

In addition, CNC milled prototype, 3D printing prototype, prototype mold making service, fixture / jig making or welding horn design and making are available in Intertech with good experience !

We need 2D, 3D parts design to start our job, we can sign NDA (if needed)

For mold making:

When making mold project, per customer’s requirement for mold steel material, we choose the suitable mold steel grade for our customers. We have high quality German and Japan imports mold steel material to proceed our mold project making. Then, the gating way will be discussed, the mold surface will be discussed, the mold cooling channel design will be checked, the operation style will be discussed, the molding machine size will be determined and the mold mechanism in actual production movement will all be checked as well. Only after our mold engineers discussing with our customers for the mold engineering in detail, we will proceed with our mold making job.

Messenger

Messenger