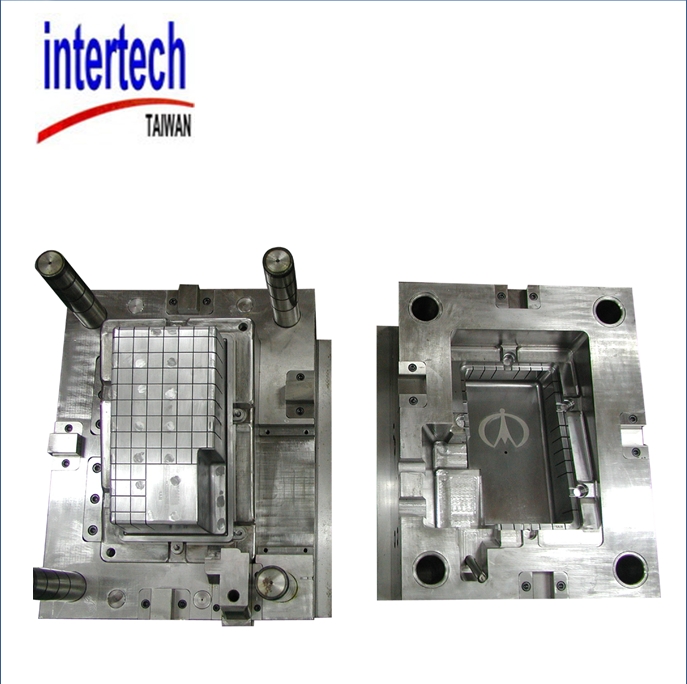

Car part mold

Intertech is a professional auto parts mold, Car parts mold,automotive parts mold,automobile parts mold & car part mold& odm die steel services Supplier. Find more auto parts mold, automobiel parts mold & car part mold &injection die & Die sets factory- Up to your project need, Intertech will customize the best die working stations either with fewservices information here or contact us for full service.

Intertech is a professional auto parts mold, Car parts mold,automotive parts mold,automobile parts mold & car part mold& odm die steel services Supplier. Find more auto parts mold, automobiel parts mold & car part mold &injection die & Die sets factory- Up to your project need, Intertech will customize the best die working stations either with fewservices information here or contact us for full service.

For mold design & mold making

- The software we use includes Pro-Engineer, I-Deas, Cimetron, Auto-Cad & Solidworks.

- Cutomer can send 2D, 3D, by .igs .stp, formats to us.

- We can provide mold flow analysis service.

- Mold design (with the best optimized mold water channel arrangement design and the best cycle time performance consideration design)

In addition, CNC milled prototype, 3D printing prototype, prototype mold making service, fixture / jig making or welding horn design and making are available in Intertech with good experience !

When making mold project, per customer’s requirement for mold steel material, we choose the suitable mold steel grade for our customers. We have high quality German and Japan imports mold steel material to proceed our mold project making. Then, the gating way will be discussed, the mold surface will be discussed, the mold cooling channel design will be checked, the operation style will be discussed, the molding machine size will be determined and the mold mechanism in actual production movement will all be checked as well. Only after our mold engineers discussing with our customers for the mold engineering in detail, we will proceed with our mold making job.

We need 2D, 3D parts design to start our job, we can sign NDA (if needed)

Quick service: 100% in Taiwan

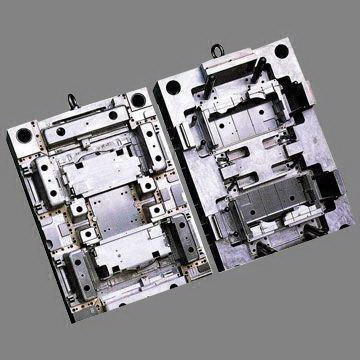

l Mold making

l Injection molding

l Tool and die making

l Tool and die production

l DFM

l Mold flow

l Conform your Industrial engineering to tooling engineering

project management by experienced engineers

l Engineering discussion is available

Taiwan Mold and Molding Factory:

l Over 30 years experience, Intertech offers customers with intelligent and cost saving mold and molding solutions to their production need in Taiwan.

l We can make the quality molds for your most complex parts and projects, including mold manufacturing, assembly, testing, and packaging.

l With 30 years experience, we manage very well in contract manufacturing, including the material selection, customer design checking, engineering discussion, tooling, pilot run, mass production, post operations, quality control and supply chain management.

l We have excellent mold making lead time, some molds 40 days, some molds even 35 days, up to your parts design.

Messenger

Messenger