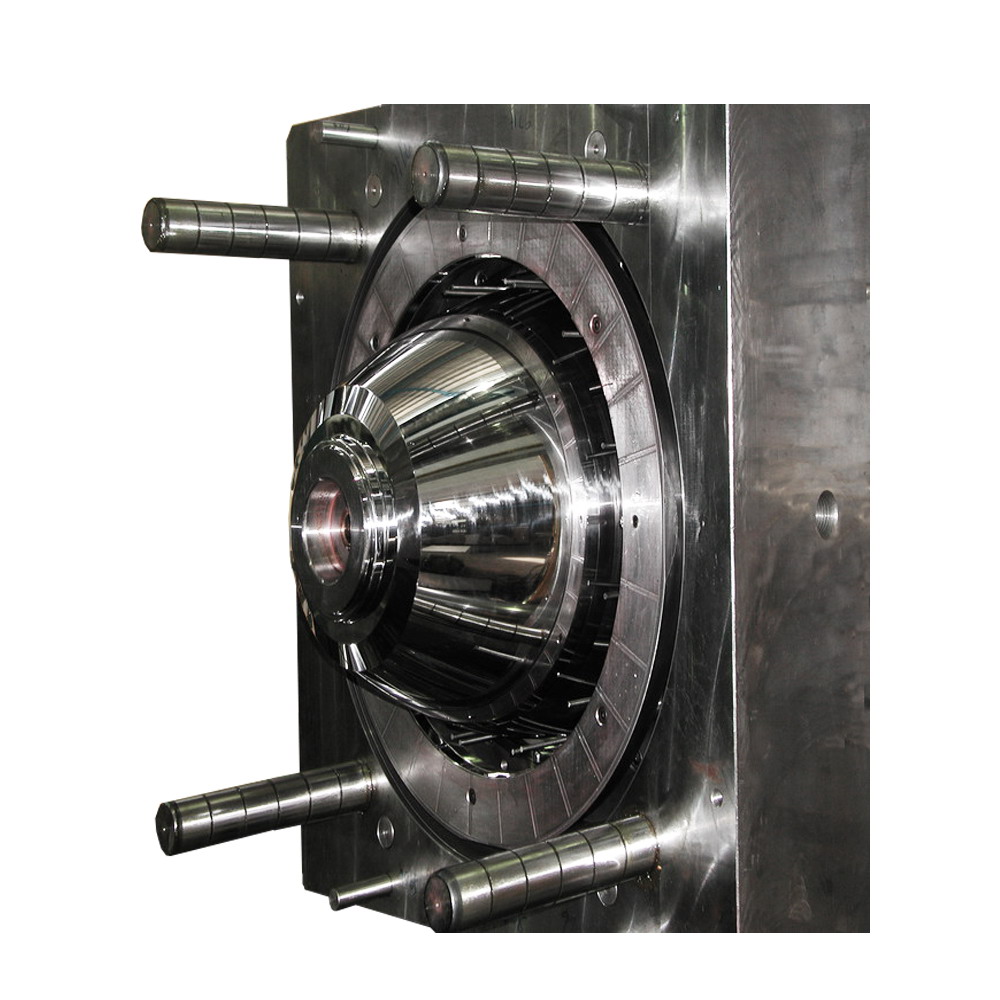

Acrylic Clear Parts LED Street Light Mold

Acrylic Clear Parts LED Street Light Mold

Mold and Molding Expert of making PC, PMMA, Acrylic Clear Parts.Intertech is an expert of making PC, PMMA, Acrylic Clear Parts.

The clear parts project we can manage includes the big ones, such as street lampshade, light and lamp housing, car lamp housing, etc.

The clear parts project we can manage includes the small ones, such us small auto car light, led lens, lab lens, optical lens, display lens, etc.

Acrylic Clear Parts LED Street Light Mold

Mold and Molding Expert of making PC, PMMA, Acrylic Clear Parts.Intertech is an expert of making PC, PMMA, Acrylic Clear Parts.

The clear parts project we can manage includes the big ones, such as street lampshade, light and lamp housing, car lamp housing, etc.

The clear parts project we can manage includes the small ones, such us small auto car light, led lens, lab lens, optical lens, display lens, etc.

Acrylic Clear Parts LED Street Light Mold

Technical Points

1. The following mold steels can all be mirror polished, but with the level difference

Ø2738-HH 34-36-HRC (Polished P20), suitable for lampshade/light housing transparent material.

Ø2738-HHH 36-38-HRC (Polished grade P20), suitable for lampshade /car lamp housing / lamp housing transparent material

Ø2083(420) 38-42-HRC, suitable for high light transmission, mirror products

2. Mold design, under Intertech’s professional experience support, will be the best optimized result for obtaining the molded parts flow mark or knit lines.

3. Mold steel will be perfectly polished to a mirror finish or texture for optical purpose.

Quick service: 100% in Taiwan

l Mold making

l Injection molding

l Tool and die making

l Tool and die production

l DFM

l Mold flow

l Conform your Industrial engineering to tooling engineering project management by experienced engineers

l Engineering discussion is available

Taiwan Mold and Molding Factory:

l Over 30 years experience, Intertech offers customers with intelligent and cost saving mold and molding solutions to their production need in Taiwan.

l We can make the quality molds for your most complex parts and projects, including mold manufacturing, assembly, testing, and packaging.

l With 30 years experience, we manage very well in contract manufacturing, including the material selection, customer design checking, engineering discussion, tooling, pilot run, mass production, post operations, quality control and supply chain management.

l We have excellent mold making lead time, some molds 40 days, some molds even 35 days, up to your parts design.

Big Clear Street Light Project

Clear Parts Project Mold and Molding

Certifications Information

Messenger

Messenger