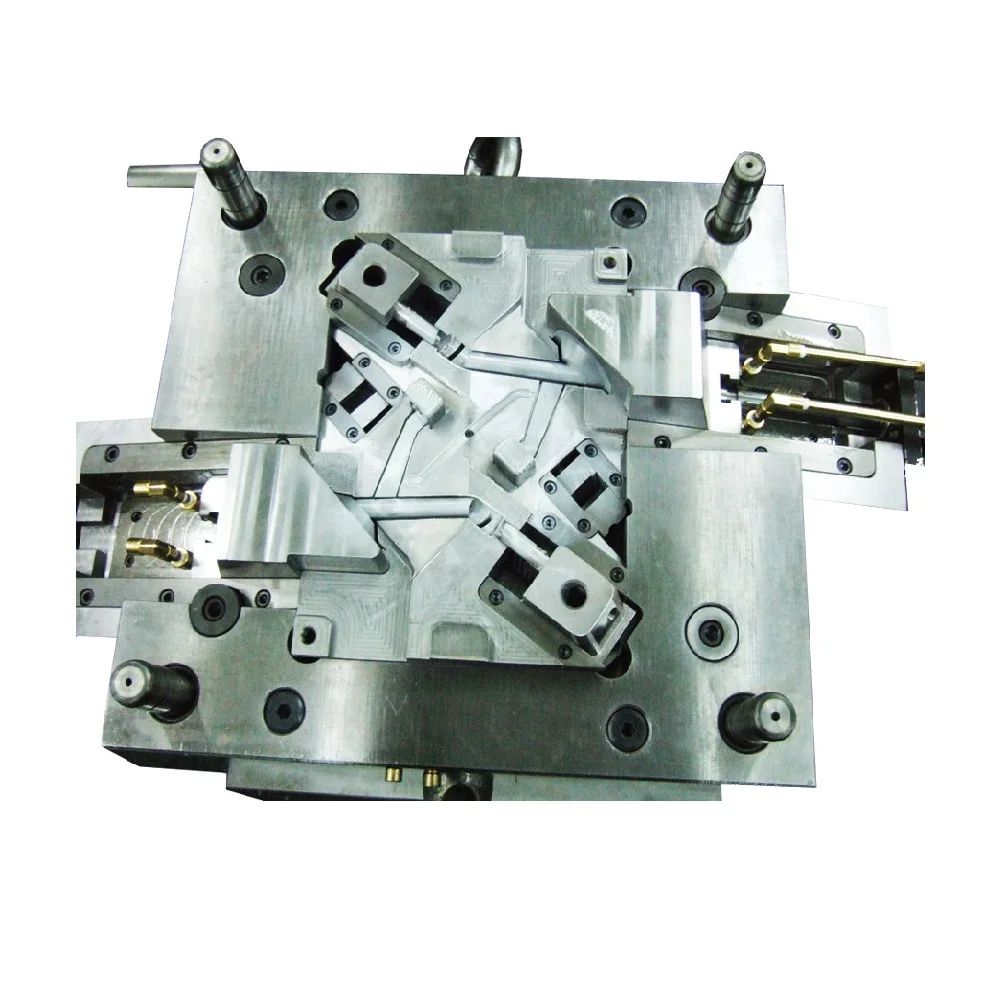

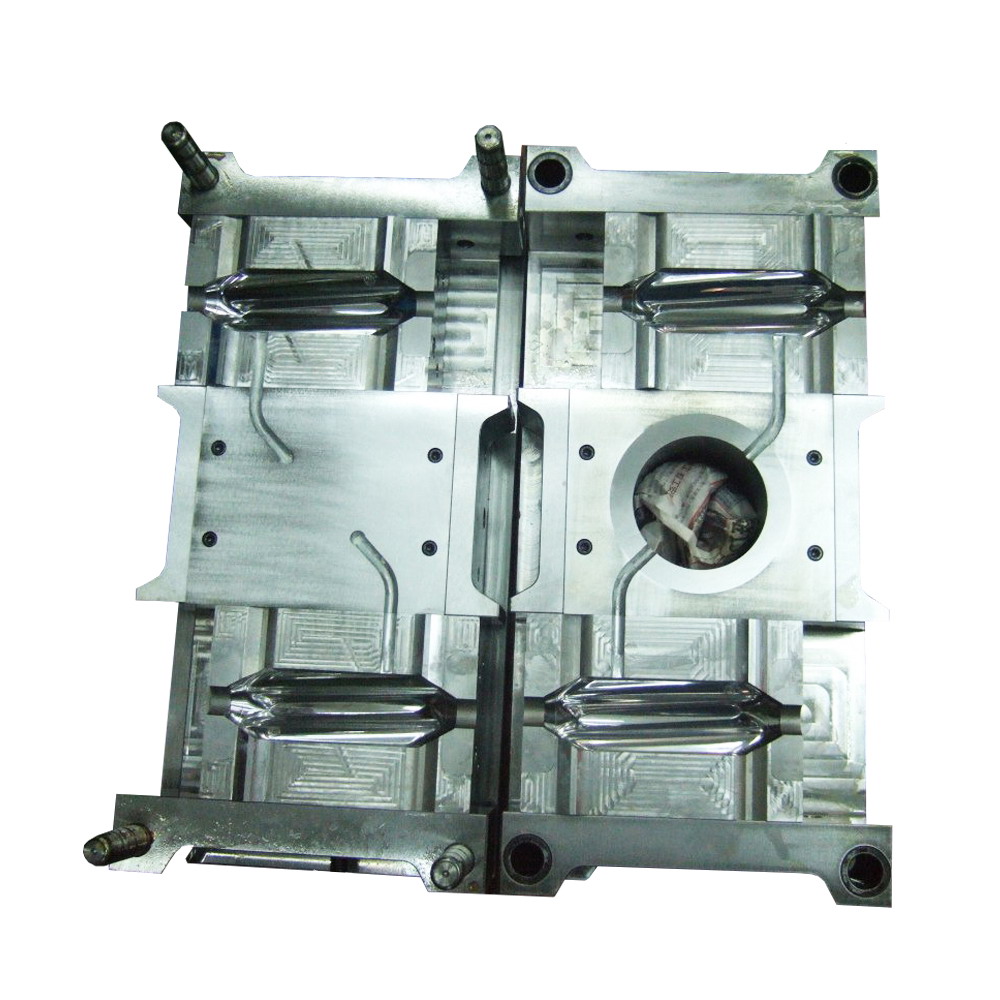

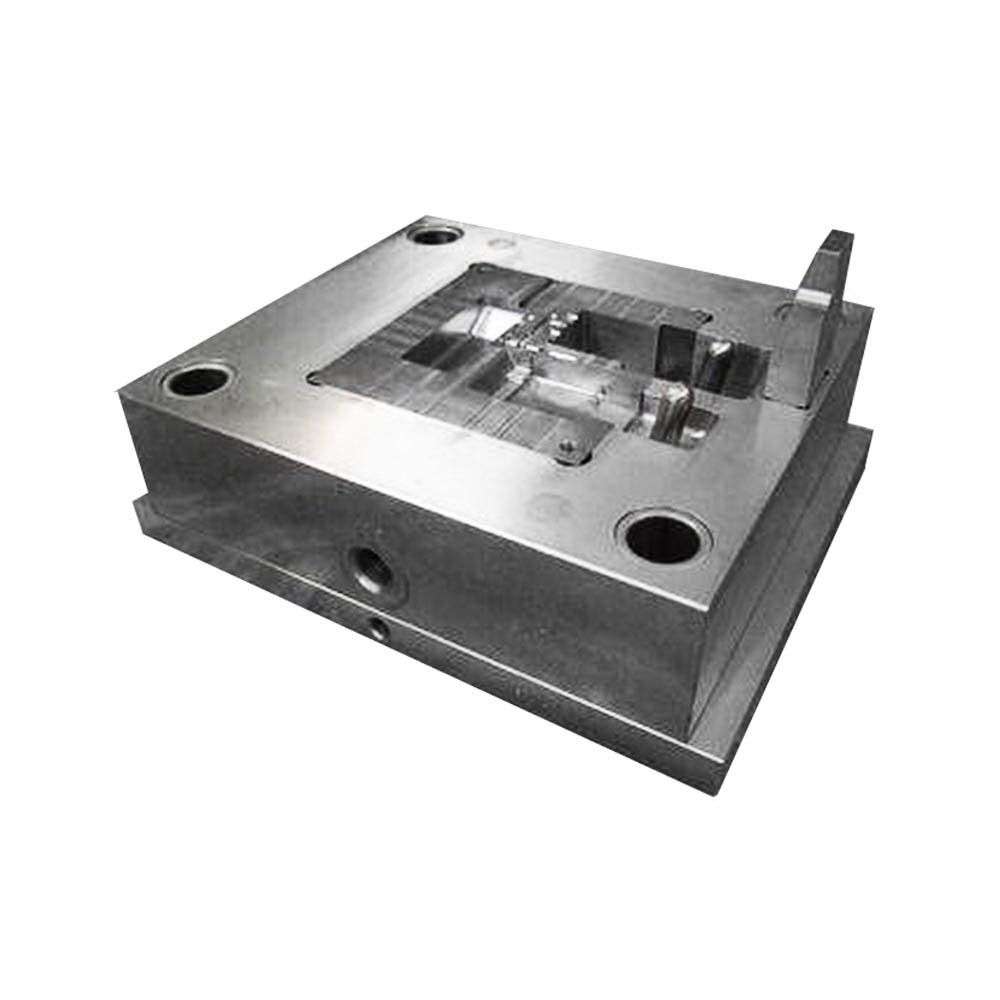

Plastic mold making

Plastic mold making Introduce

Intertech is a professional plastic mold manufacturer in Taiwan.

We have more than 30 years experience of making plastic injection mold.

- The plastics for the plastic molds we manage: mostly is with PC, PMMA, ABS, PP, nylon plus glass fiber..etc.

- The plastic mold steel we manage: mostly is with P20, H13, 420 stainless steel, 100% imports from German and Japan.

- The technical type of plastic mold we manage: mostly with forced ejection, two plate mold, three plate mold, automatic drop mold, fast cycle mold and high speed mold.

Plastic mold making Introduce

Intertech is a professional plastic mold manufacturer in Taiwan.

We have more than 30 years experience of making plastic injection mold.

- The plastics for the plastic molds we manage: mostly is with PC, PMMA, ABS, PP, nylon plus glass fiber..etc.

- The plastic mold steel we manage: mostly is with P20, H13, 420 stainless steel, 100% imports from German and Japan.

- The technical type of plastic mold we manage: mostly with forced ejection, two plate mold, three plate mold, automatic drop mold, fast cycle mold and high speed mold.

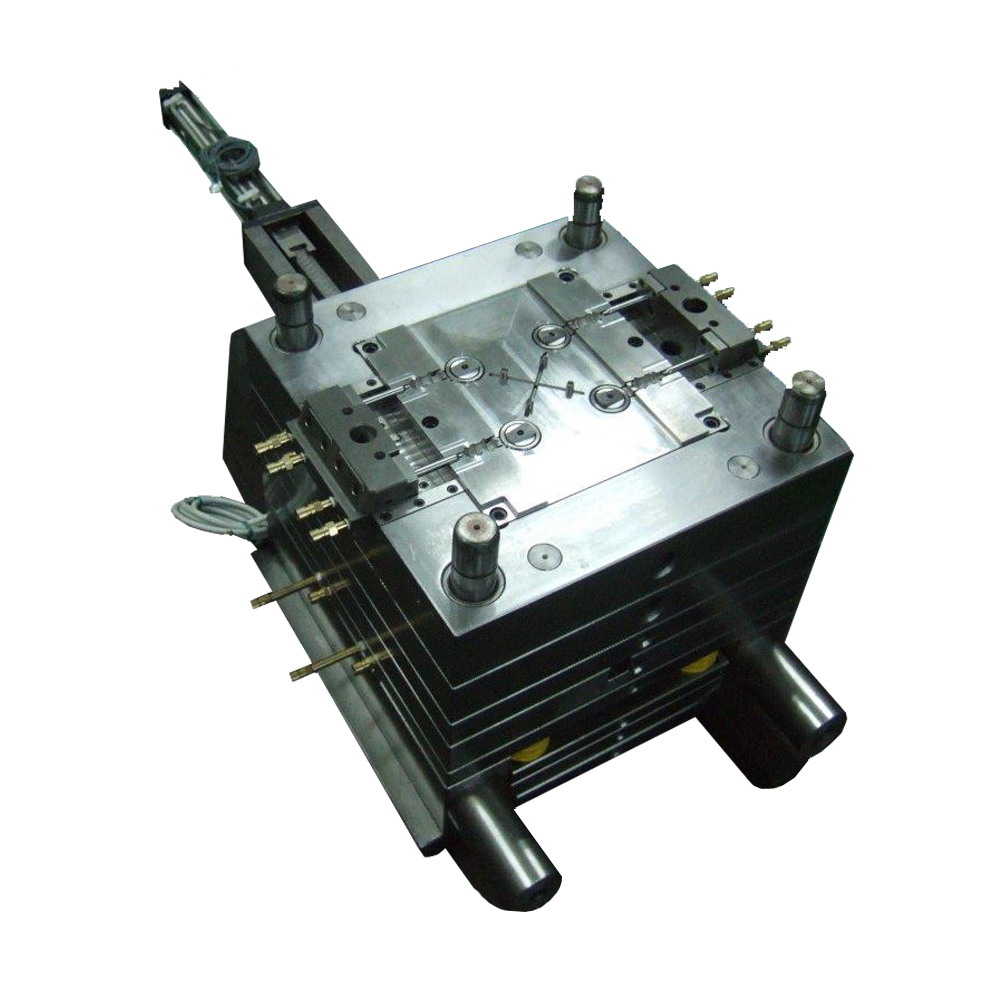

Plastic mold making Service

Taiwan Mold and Molding Factory:

l Over 30 years experience, Intertech offers customers with intelligent and cost saving mold and molding solutions to their production need in Taiwan.

l We can make the quality molds for your most complex parts and projects, including mold manufacturing, assembly, testing, and packaging.

l With 30 years experience, we manage very well in contract manufacturing, including the material selection, customer design checking, engineering discussion, tooling, pilot run, mass production, post operations, quality control and supply chain management.

l We have excellent mold making lead time, some molds 40 days, some molds even 35 days, up to your parts design.

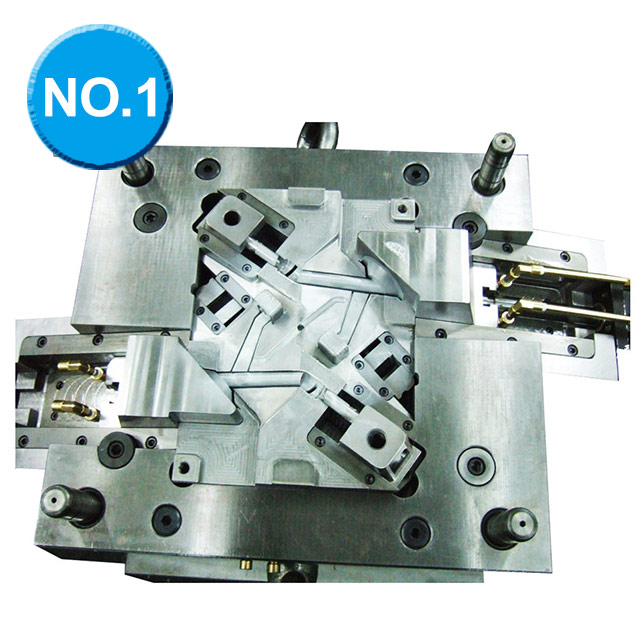

Plastic mold

Plastic injection mold

OEM plastic mold

Buying Guides

1. Customized Making:

- Per your drawings or samples, we can customize your mold.

- Per your requirement, we can modify and design your parts structure to establish the overall 3D effect drawing. And per above 3D drawing, we can provide mold making quotation and product molding quotation to you to help you to do the entire costing analysis.

2. Prototype Making:

- in initial stage, after confirming the product design, size, material, and price…etc, if you need, before starting to make the real mold, we can make the prototype for you to help you understanding the product detail and its outlooking (Ps. we will estimate the prototype cost report to you from 3D printing or from NC milling way).

3. Purchase Contract Making:

If both of us agree to sign the contract, we will mention the working detail, lead time, inspection standard, payment term information…etc on the contract.

4. During the mold manufacturing period:

- We will send the update working progress report in every 1-2 week with photos.

- Before commencing making the mold and the machining process, if customer needs to adjust the product’s shape slightly, we will not charge the extra cost.

-If the machining process is on-going, and customer needs to adjust the product design, we will study and give our report to see whether we should charge extra cost or not.

-We will send T1, T2 or T3 samples till meeting customer’s satisfaction.

5. If customer places the product production orders to us:

- After the final trial samples is approval by customer, if customer places the product production to us, we will be responsible for the mold maintenance and performance for all.

6. Packing information:

- For mold, we pack with standard exported wooden box with fumigation process.

- For product, if there is no specific packing requirement, we will use regular carton box and bag (free of charge). If customer requires specific packing way,

We can help customer to do the assembly, packing and the printing from case to case.

7. Transportation:

- Customers can use their own forwarder or we can help customer to arrange any sea or air transportation forwarder to deliver the goods to customer’s address.

Product Highlight:

|

Product Name |

Plastic mold making |

|

Plastic Materials: |

PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30% |

|

Mold Structure: |

Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

|

Mould Base: |

HASCO standard, European standard, World standard |

|

Surface Finish: |

Texture (MT standard), high gloss polishing, Mirror finish etc |

|

Cavity / Core Steel: |

P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

|

Cavity: |

Single cavity, Muti Cavity, based on customer’s requirement. |

|

Hot / Cold Runner: |

HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Taiwan made brand…etc. |

|

Mould Life: |

1,000 to 1,000,000 shots (according to your working environment) |

|

Softwares: |

CAD, CAM, CAE, Pro-E, Solid works…etc. |

|

Equipments: |

High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

|

Mold Lead Time: |

T1, 20~50 days, parts measurement report (upon required). |

|

Annual Output |

250 sets of mold |

Contact us

Intertech makes good quality new custom mold and molded parts for any plastic, silicone and metal project, please send us your project now !

Sample order is available after our discussion !

We can give you some suggestion for our best selling mold and molding parts project working way !

May we have your Whatsapp number ? we can talk there more quickly or you can add ours Whatsapp: +886.9328.66329

Messenger

Messenger